220 years of change: How two centuries of workplace Health and Safety has improved lives

From child labour and frequent deaths in the workplace to us now having some of the safest working environments in the world, health and safety legislation has shaped not just the workplace but society as a whole.

Business health and safety has come a long way from the 1800s when it was shockingly just the norm for workers to be endangered by their jobs. In 1802, when the UK introduced its first Act of Parliament to protect the welfare of people at work, employees faced losing limbs, being burned and blinded, and even dying in the workplace every day – with many workers being younger than the age of nine.

The Health and Morals of Apprentices Act was introduced in 1802 to reduce the working hours for those employed in cotton mills and factories. Later, the Factories Act 1833 imposed a minimum age for child workers. Thanks to the more recent introduction of the Health and Safety at Work Act 1974 and the Health and Safety Executive (HSE) being formed a year later, workplaces have become increasingly safer.

In the present day, every employer not only has a legal duty to protect the health, safety and wellbeing of their emplyees but can face serious consequences if health and safety regulations are not followed. It’s now reassuringly the norm to be kept safe at work and new legislation is frequently implemented alongside regular updates to the UK’s existing health and safety laws - such as updates to HSE legislation. Management of health and safety policies and procedures should be a top priority for all businesses, and our experts at phs Besafe can provide the highest quality products and advice to help employers stay compliant.

To see how business health and safety has changed over the years, we’ve picked out some of the most significant events that have helped to shape the modern workplace as we know it and form the general health and safety practices that businesses of all sizes use today.

Britain’s health and safety timeline: 1800s to now

1802: Health and Morals of Apprentices Act 1802

This was the first Act of Parliament passed to protect the welfare of employees. Its full title is the ‘Act for the preservation of the Health and Morals of Apprentices and others employed in Cotton and other Mills, and Cotton and other Factories’. It was passed by politician (and later Prime Minister) Sir Robert Peel due to the abuse of children working in texture mills and the poor conditions they experienced in these premises.

The introduction of this Act in 1802 limited labour to 12 hours a day and prevented pauper apprentices from working during the night. It also dictated that apprentices should be educated in reading, writing and basic arithmetic, and supplied with adequate clothing and sleeping accommodation. Additionally, this Act outlined that such environments should be washed on a regular basis; once a week for floors and two or three times a year for walls and ceilings.

1833: The HM Factory Inspectorate and The Factories Act 1833

The first version of the Factories Act was introduced due to pressure from the ‘Ten Hours Movement’. This originally emerged in 1831 and sought to satisfy millworkers’ demand for a 10-hour day. Although the Factories Act 1833 maintained the maximum 12-hour day for children and other young workers in cotton mills and other factories, it was extended to include linen and woollen mills. Some of the other changes it implemented were that no child workers could be under nine years of age and each child was required to have two hours of schooling per day. The Factories Act was later revised in 1844 to prohibit the cleaning of factory machinery when it is in motion and in 1847 to limit women and children between the ages of 13 and 18 to work a maximum of 63 hours per week.

Under the provisions of this Act, the HM Factory Inspectorate was formed and the first inspectors were appointed in factories. They were responsible for around 3,000 texture mills and had the power to formulate new legislation to ensure the Factories Act was adhered to.

1837: recognition of duty of care to employees

Although not the passing of a new Act, 1837 is notable for being the first time it was enforced that an employer has, in a common law, a duty of care to employees if a breach resulted in an injury or other harm to their health. In the Priestley v. Fowler (1837) case, it was ruled that Thomas Fowler of Market Deeping was responsible for injury caused to his servant, Charles Priestley, when working.

1842: Coal Mines Act 1842

This Act was implemented as a result of public outcry. A Report by a Royal Commission that year found that accidents, lung disease, brutality and long working hours were the norm for people working in the coal mines, causing a new Coal Mines Act to prohibit women of all ages from underground work. Boys aged 10 and under were also excused, though this age limit rose to 12 in the year 1860.

A year later, the Mines Inspectorate was formed to ensure all mines and collieries had an appointed inspector. The first inspector was Hugh Seymour Tremenheere, who was responsible for reporting on serious and fatal incidents in the mines and making recommendations to training managers. However, he wasn’t permitted to enter the mines to inspect them. It wasn’t until 1850 that inspectors were able to enter the coalmines.

1878: Factory and Workshop Act

Bringing all the previous acts together, this act is referred to as the first attempt at comprehensive factory legislation. Applying to all trades, it included banning the employment of children under 10 with 10-14 year olds only being able to be employed for half days. Women were only allowed to work for a maximum of 56 hours a week and compulsory education for under 10s was established.

1880: Employers’ Liability Act

Workers who were in accidents caused by negligence (from managers, superintendents, foremen and, in railways, by signalmen, drivers and pointsmen) were now protected.

1897: Workman’s Compensation Act

This Act created a scale of compensation payments from employers to employees in specific industries who suffered injuries at work.

1931: Factories Act

The latest version of this Act laid out a comprehensive code for safety, health and welfare to all factories. In 1961 it was amended to govern dangerous processes.

1954: Mine and Quarries Act

This Act set out the most comprehensive safety regulations across any industry. It set out rules for equipment, access, hazards, working methods as well as inspections and statutory duties on mine managers.

1956: Agriculture (Safety, Health and Welfare Provisions) Act

The introduction of this Act focused on implementing comprehensive health and safety protection for workers in the agricultural industry and children who may come into contact with agricultural vehicles, equipment and machinery. It prohibited excessive heavy lifting and outlined provisions of sanitary and washroom facilities and requirements for first aid.

That same year, the Health and Safety Commission (HSC) was also established in conjunction with the Act. The purpose of the commission was to conduct research into health and safety in order to propose and implement new legislation.

This Act gave statutory protection to what was a large remaining group of unprotected workers; shop workers and office workers.

1964: First use of high visibility workwear

Protective high visibility clothing was first introduced to the UK this year when it was trialled by railway maintenance workers in Glasgow. These workers were provided with hi-vis vests from their employer, The Scottish Rail Network. It was agreed that these were effective at making workers more visible, so by 1965, everyone working on the West Coast Main Line (which connects Greater London to Scotland), was provided with high visibility clothing as standard.

1974: Health and Safety at Work etc Act 1974

Now the most important piece of health and safety legislation in the UK, the Health and Safety at Work Act was first introduced in 1974 to provide a standard legal framework to protect employees (including temporary workers and trainees). One of the primary responsibilities of this Act (which every employer is legally required to comply with) is to take appropriate steps to ensure the health, safety and welfare of people at work. Although it was initially called “a bold and far-reaching piece of legislation” by HSE’s first Director General, John Locke, at the time of its implementation, it now forms the basic framework for managing workplace health and safety in the UK.

1975: Health and Safety Executive (HSE)

The Health and Safety Executive (HSE) was formed a year after the establishment of HSC and HASAWA. Its aim was to enforce health and safety in workplaces across the UK by undertaking the requirements of the new Health and Safety Commission. As part of this, many regulatory and scientific organisations concerned with workplace health and safety were transferred to HSE, such as the Factory Inspectorate and the Safety and Health Division from the Department of Energy. Today, HSE remains the regulator that enforces the protection of health, safety and welfare in workplaces, with responsibilities including to provide advice to employers and employees, and conducting research and inspections. HSE legislation continues to be updated on a regular basis - ensuring businesses' obligation to the health and safety of their workers remains central.

1981: Health and Safety (First Aid) Regulations 1981

These regulations, which came into force in July 1982, outlined that employers must provide adequate equipment and facilities to allow first aid to be provided to employees if they become ill or injured at work, as well as any visitors to your business premises. This includes educating employees on the first aid facilities available, where they’re located in the building, and how to use them (if necessary).

1992: Personal Protective Equipment at Work Act 1992

Almost 30 years after hi-vis vests were first trialled in the UK by Scottish railway workers, the Personal Protective Equipment at Work Act was implemented to ensure that all employees should be provided with PPE (Personal Protective Equipment) in any working environments where it is necessary to ensure their health and safety. This Act dictates that employers are responsible for providing this PPE, as well as correctly maintained and stored when not in use. PPE includes (but isn’t limited to) googles, gloves, helmets and protective clothing.

1994: EN471 standard for high visibility clothing

The BS EN471 was introduced to implement an industry standard for high visibility clothing for workers in the EU and the UK. The BS EN471 (also known as the European standard for High Visibility Clothing), separates high visibility garments based on the level of visibility they provide into 3 Classes, with Class 1 offering the highest level of protection. The standard was superseded by EN ISO 20471: 2013 and was last reviewed in 2018.

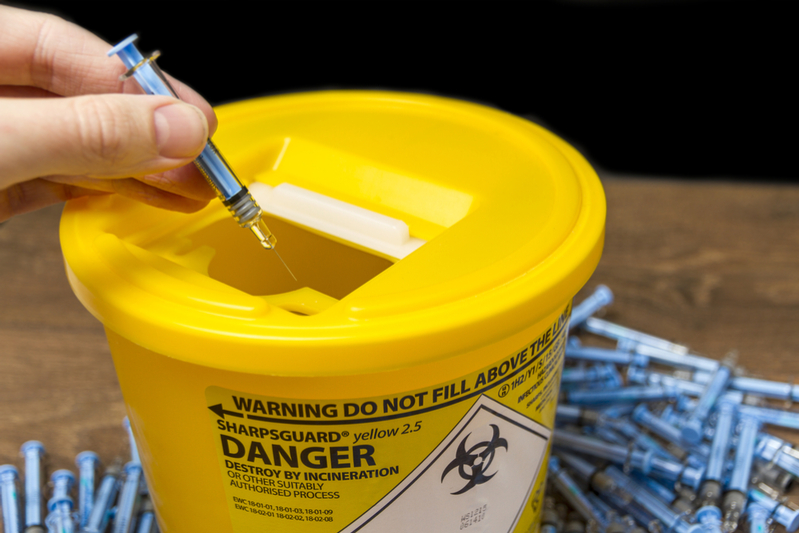

2013: Health and Safety (Sharp Instruments in Healthcare) Regulations

These regulations were introduced to ensure employers prevent the reduce risk of harm from medical ‘sharps’ (such as needles) used in the healthcare sector. They require all employers and contractors in healthcare to train employees on the risks of sharps and provide suitable arrangements to ensure their safe use and disposal. The regulations also dictate that employers and contractors must investigate all work-related incidents involving sharps.

In terms of health and safety, the modern workplace bears barely any resemblance to the life that workers of the 18th and 19th centuries faced on a daily basis. Even just a few decades ago, workplace injuries and even deaths were not that uncommon. However, the Health and Safety Act of 1974 revolutionised the workplace and we now enjoy significantly safer conditions than previous generations.

As we strive for continuous improvement, there are frequently new regulations and refreshes to existing legislation. Staying on top of these changes to ensure you’re always abiding by the law and maximising workplace safely can sometimes be challenging, but it is nonethless essential. Employers now have a greater responsibility than ever to ensure the safety of their employees and can face serious consequences if they do not comply with the latest UK legisaltion - risking criminal prosecutuion, fines and more serious penalties. This does not simply mean that if an employee is harmed, companies can face consequences. Causing a risk of harm is also an offence. It is therefore important to ensure you health and safety policies and procedures are compliant, and that all staff adhere to these.

To ensure your work environment is compliant, and avoid the consequences of not following the latest legislation, policies and procedures, check out the HSE website for updates.

Sources:

http://www.hse.gov.uk/aboutus/timeline/index.htm

https://www.historyofosh.org.uk/timeline.html

https://www.bbc.co.uk/news/magazine-14720101

http://www.nationalarchives.gov.uk/education/resources/1833-factory-act/

https://www.globalrailwayreview.com/article/30804/visibility-rail-safety/

http://www.hse.gov.uk/enforce/our-role-as-regulator.htm#

https://www.parliament.uk/about/living-heritage/transformingsociety/livinglearning/19thcentury/overview/coalmines/