The Evolution of High Visibility Protective Workwear

High visibility clothing is an important part of workplace safety. It is worn by all kinds of people across a range of industries and has even made its way into sport and fashion.

The evolution of high visibility clothing represents an important change in workplace safety measures. Employers have a responsibility to ensure that employees are given the tools and equipment to do their jobs safely and make sure they adhere to workwear standards.

How has high visibility clothing changed over the years, and how effective is it today? We’re here to guide you through the evolution of high visibility clothing.

A brief history of workplace safety

The Industrial Revolution brought with it a whole new approach to work. But working conditions were generally poor, especially for children who often worked long days in factories. These conditions were finally recognised with the introduction of the Health and Morals of Apprentices Act 1802, which also became known as the Factory Act. Its aim was to improve child labour conditions and became the first in a line of legislation introduced to protect workers’ health and safety.

Fast-forward to the Health and Safety at Work Act 1974, which puts the responsibility for health and safety in the workplace on employers and employees. It continues to be updated and amended today, and has led to significantly fewer fatalities and accidents in the workplace.

What is high visibility clothing made from?

The origins of high visibility workwear are found in the 1930s, when Bob Switzer was injured while unloading crates at a Heinz Ketchup factory. He was injured so badly that he went into a coma and his eyesight was permanently damaged.

To help his recovery, Switzer spent time in a dark room where his brother entertained him using fluorescent chemicals. Once fully-recovered, Swizter experimented further with fluorescent chemicals and the brothers invented the first fluorescent paint;

also known as high visibility paint.

After Switzer's discovery, scientists and engineers began exploring other ways of using fluorescence. During World War II, the U.S started experimenting with using high visibility garments to reduce friendly fire and to communicate between ground and

air troops. High viz buoys were also used to distinguish what parts of the sea had been searched for explosives.

A significant step in its use in workwear was made in 1964, when Scottish Rail became the first company to introduce high visibility workwear to the rail services due to a high number of safety concerns. The success and importance

of this is apparent, as by 1965 every rail worker on the West Coast Main Line was issued with high visibility garments.

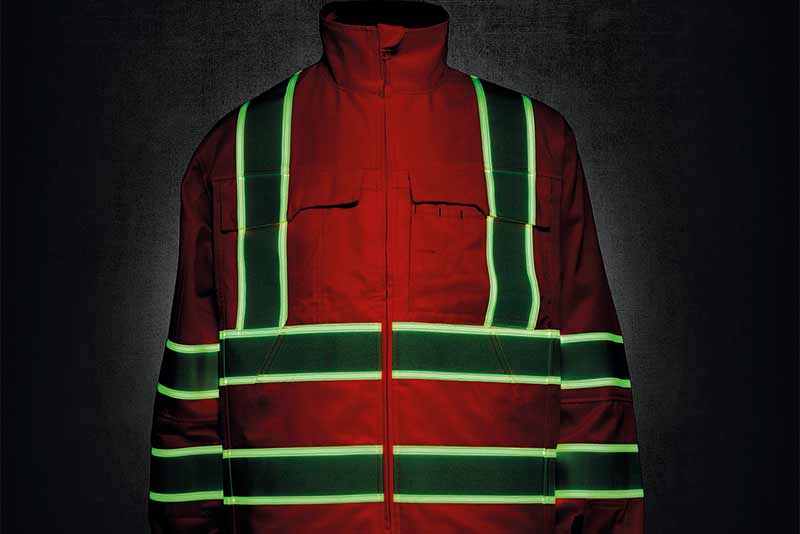

How does high visibility fabric work?

High-visibility workwear is made from fluorescent material. Natural or artificial light reacts with the fluorescent colour, which makes the fabric appear flow. The reflective strips on high-visibility workwear is to help

with protection in the dark. Light Sources, such as cars or torches will cause the strips to glow. For protection in any environment, including wet weather, high-visibility workwear should have a mix of fluorescent colours

and reflective strips.

How often should you replace your high-visibility clothing?

High -visibility clothing should be regularly checked to confirm it has retained its glowing qualities after being washed. It is important to regularly clean high-visibility safety workwear as dirt can hinder

its effectiveness.

There is no set time that you should replace high-visibility safety clothing, as there are a number of varying factors; such as the number of wash cycles or any damage to the fabric. Credible manufacturers should provide you with

detailed wash cycle information, you should follow these instructions carefully. You should do a quick check before every use, it could save your life.

When should high visibility clothing be worn?

In 1974, the Health and Safety at Work Act was first put in place in the UK. This determined the requirements that employers needed to follow in

regard to their employees’ safety. Ensuring that workers are seen when working in potentially dangerous situations was a key requirement of the ACT.

In 1992, we then saw the introduction of the Personal Protective Equipment (PPE) at Work Act. This act states workwear must be appropriate for the conditions

in which an employee is working. The workwear must also fit them correctly in order to protect be compliant with health and safety policy.

The EN471 standard was a specification for high visibility clothing that was introduced in 1994. This standard, however, was superseded by an adapted version in 2003. The standard worked on a class system stating the required amounts

of background to reflective material ration. These classes were then assigned to specific jobs based on how dangerous not being seen could be.

In 2013, the EN ISO 20471 was introduced. It stipulated that regulation must be adhered to on an international basis, rather than just in the EU.

The importance of high-visibility clothing today

High visibility clothing has a number of benefits that make it an essential health and safety measure. Some of the key benefits include:

Provides visibility for employees, ensuring they’re noticed by others and can be seen at night and in poor weather/low visibility conditions

Different styles ensure protection for all seasons, including lightweight options for the warmer months and thicker items to provide warmth during the winter

Having a supply of high visibility clothing for your workplace helps maintain health and safety standards across your business or organisation, ensuring employees always have access to what they need.

Choosing high visibility solutions for your workplace

Today’s modern high visibility clothing solutions provide a wider choice for employers, ensuring employees stay safe in all kinds of work environments. From bright gear to glow gear and even foul gear, there are different types of safety clothing to choose from.

Some tips for choosing the right high visibility clothing include:

Make sure the clothing is suitable for the environment and the risks involved.

Ensure high visibility clothing fits properly – loose clothing can pose a hazard in some environments

High visibility clothing should be comfortable for the wearer, particularly during long shifts or challenging working conditions

Does it meet EN ISO 20471 standards? All high visibility clothing should be manufactured to this standard

Is it compatible with other forms of PPE?

Choose phs Besafe for high visibility clothing

phs Besafe is one of the UK’s leading suppliers of high visibility clothing. Our essential safety wear is designed for optimum functionality, durability and protection. We offer a tailored workwear service that provides you with everything you need, no matter the size of your business or organisation.

In addition to supplying workwear, phs Besafe also provides laundry and locker services, as well as garment destruction where needed. Whatever your needs, we’re here to help. Contact us today for more information.